Exploring Kentucky

May 2024. When driving through Kentucky at his time of year you could almost think you were in Scotland, as rolling green hills and farms zip by. But once you hit the town of Lawrenceburg, where the distillery is located, this changes. You can only be in one place, and it is definitely not Scotland. The quaint main street is lined on either side with colonial buildings, each adorned with a fluttering stars and stripes flag. This is Kentucky.

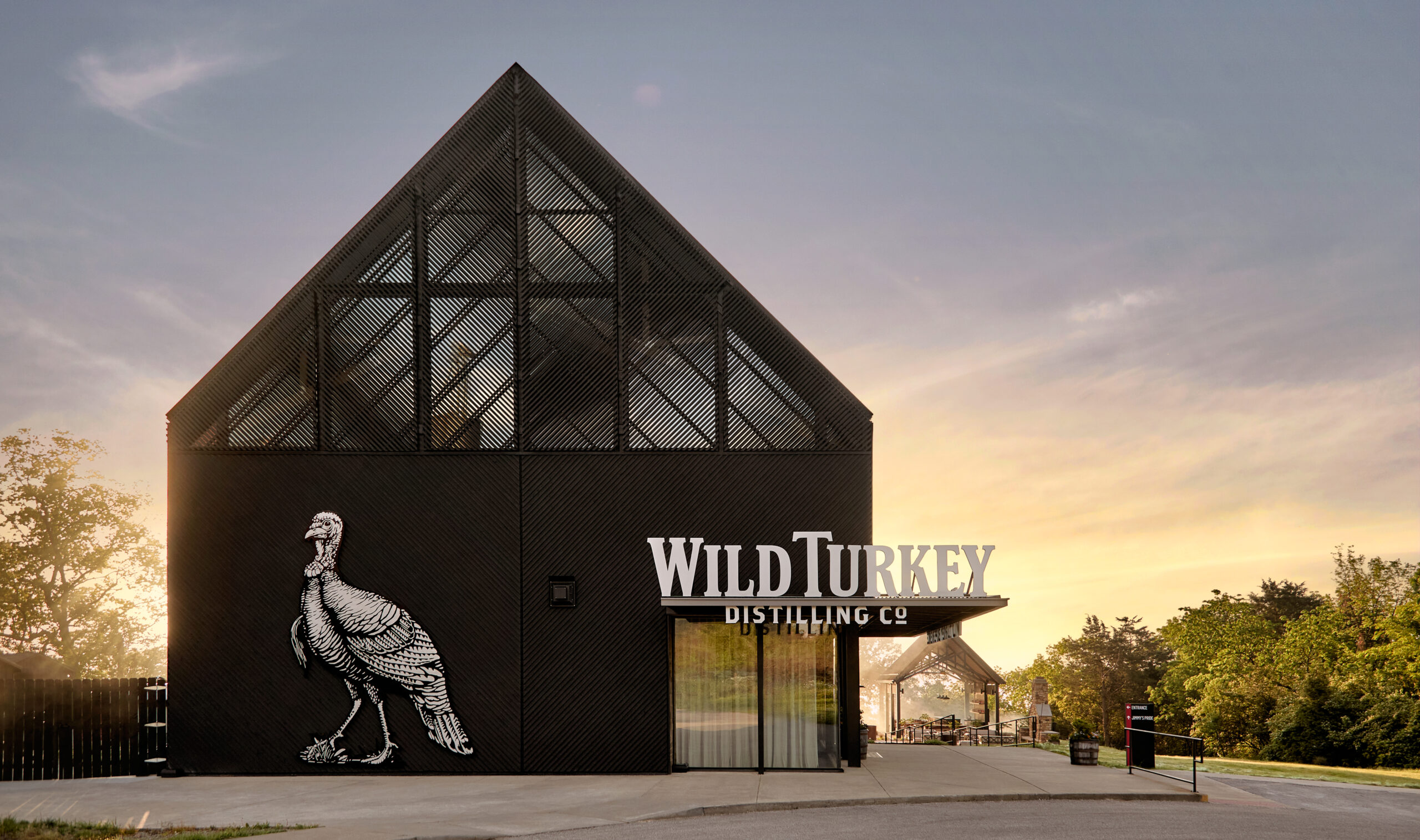

Wild Turkey is located on the edge of town and is a huge facility. The site boasts a distillery capable of producing a staggering 41.5 million litres (11 million US gallons) of whiskey per year, 32 rick houses (the American name for a whiskey warehouse) and a brand-new visitor centre to welcome tourists and whiskey fans alike.

Brand beginnings

The brand has an interesting and slightly unorthodox history. First bottled by spirits wholesaler Austin Nichols in 1941, it featured whiskey from the Old Hickory distillery in Tyrone, Kentucky. Its origin is said to have come from the previous year when an Austin Nichols executive took some cask samples for guests on a turkey shoot. When he got asked back the following year, he was asked to bring more of ‘that wild turkey bourbon’. The rest is history, as they say.

Fast forward 70 years and Wild Turkey is one of the best-selling and most-awarded bourbon whiskey brands in the world. The distillery was built in 2010, just one year after current owners Gruppo Campari took over. They are in the process of building an extension which is due to open in 2026 and will increase capacity by 50%. Most of the time is spent producing their famous bourbon, with two to three days per month allocated to the production of rye whiskey.

All in the mixture

Wild Turkey bourbon has a mash bill (the name given to the mixture of cereals used) of 75% corn, 13% rye and 12% malted barley. Its rye whiskey on the other hand has a mash bill of 52% rye, 36% corn and 12% malted barley. But how else does making bourbon differ from the traditional Scotch single malt process?

Firstly, the cereals are put through a hammer mill – this apparatus is common in American whiskey production and gives a courser grind than a Scottish roller mill. It is also often used in brewing beer. The cereals are then cooked, rather than mashed, to extract the desired enzymes and sugars. Corn takes the longest time to ‘cook’ and requires the highest temperature (around 200°C). Then rye is added, and the temperature lowered, and finally the malted barley. The temperature is lowered further.

The mash is then cooled before being transferred to one of 24 huge open top fermenters (these are called washbacks in Scotland). The proprietary yeast strain, which is recorded to date from just after Prohibition, is added and left for just over three days (78-80 hours) to do its job by converting all the natural sugar to alcohol. The result is a 12-15% ABV ‘beer’ – this is higher than wash produced in Scotland, which is around 7-8% ABV.

Distillery differences

The still at Wild Turkey is HUGE. There are no picturesque copper pot stills here as you find in a Scotch single malt distillery. This is a column still that stands 52 feet tall (15.8 metres) but with just a five-foot diameter (1.5 metre). It can be operated 24 hours a day, seven days a week. The alcoholic beer is heated, solids and all, and evaporates before being condensed back to a higher percentage spirit. The first distillate is then redistilled a second time.

The distillery runs the still at a very high temperature to create the desired lower strength of spirit (the legal maximum for bourbon is 160 Proof/ 80% ABV). Wild Turkey comes off its second distillation at 130 Proof/ 65% ABV). This is then reduced further to 115 Proof/ 57.5% ABV with water, before being put into barrels for maturation. And when I say, ‘very high temperature’, I mean it. That still house was the hottest I have ever set foot in. It was roasting!

Storage similarities

The rick houses also have a very different feel to a Scottish warehouse. There are no dunnage warehouses here with their stone walls and earthen floors. The rick houses are massive and have many casks stored on racking, like the Lowland Bond where Whisky 1901 hold client casks.

The ones at Wild Turkey are five storeys high and can hold 15,000 barrels at any one time. They also have several palletised rick houses, where casks are stacked up to the roof. These hold 20,000 barrels. The scale is immense.

Brands such as Wild Turkey supply their used barrels to many locations once emptied. The law states that bourbon can only be matured in new American oak, so therefore the casks cannot be used a second time. This may seem like a waste, but many go to Scotland to be filled with Scotch whisky. Also, to Ireland, Japan and beyond. Other outlets include the Caribbean for rum maturation, France for Cognac and Mexico for tequila and mezcal.

A warm visitor welcome

-

-

© Wild Turkey

-

-

© Wild Turkey

-

-

© Wild Turkey

-

-

© Wild Turkey

The newly opened visitor centre is excellent also – contemporary, welcoming and uses the space well. It is named after Jimmy Russell, the legendary Bourbon Hall of Famer who began working at the distillery in 1954. He still visits almost daily. His son Eddie is the current Master Distiller, with his grandson Bruce waiting in the wings. The Russells are a true whiskey dynasty.

The visitor centre features a timeline wall tracking the history of Wild Turkey and the Russells, plus a mezzanine bar that gives fantastic views to the Kentucky River, two tasting rooms and a well-stocked shop. There is also an outdoor space for enjoying a cocktail or two at leisure.

I loved my visit to Wild Turkey and urge any of you that are in Kentucky to swing by for a tour and tasting. You will get the warmest of welcomes and see everything for yourself. I found it fascinating to swap my familiarity of the Scotch whisky process with that of bourbon. I learned a lot and hope you have too from this article. Look out for the next one in my American series soon.

Get in touch with the experts at Whisky 1901 to find out more about the whisky distilling process and how you can start your own whisky journey by investing in a cask of Scotch.